CrossAssembly Supply Chain Management

Sorglos von A wie Auftragsbestätigung bis Z wie Zulieferung: Wir bieten Ihnen eine sichere Gesamtlösung für die Auftragsabwicklung und Produktionslogistik. Profitieren Sie jetzt von unserer langjährigen Erfahrung und wirtschaftlichen Denkweise als 1-tier OEM-Lieferant.

Unsere Supply Chain für Ihren Erfolg

Nach Ihren spezifischen Bedürfnissen unterstützen wir Sie als Berater, Entwicklungs- und Produktionspartner, Einkäufer, Hersteller, Lieferant, Projekt- und Qualitätsmanager.

With the claim to offer our customers a reliable and flexible service and to be able to guarantee an effective resource optimization with permanently highest quality and flexibility, we have been relying on secure and long-term supply sources and a top-modern EDI architecture for years. Now you can benefit from our many years of experience as a 1-tier OEM supplier of assemblies and equipment. In doing so, we pursue three overriding goals.

Ihre Zufriedenheit

Wir garantieren dauerhaft höchste Qualität durch regelmäßig geschultes Personal. Unsere flexible Produktionsplanung und die Redundanz in der Personalplanung sichern höchste Anpassungsfähigkeit. Dank einer top-modernen EDI-Infrastruktur und konsequentem Product Data Management gewährleisten wir effiziente Abläufe und transparente Prozesse.

Stabilität

Lieferengpässe gehören der Vergangenheit an – durch die Redundanz unserer Lieferquellen. Wir setzen auf sichere, größtenteils regionale Partner und Lieferanten. Die Prozesssicherheit wird durch regelmäßig geschultes Qualitätspersonal und vollständig digitalisierte Fertigungsprozesse gewährleistet.

Ressourcenoptimierung

Mit unserer nahtlosen Auftragsabwicklung unter einem Dach bieten wir höchste Effizienz. Je nach Bedarf realisieren wir Just-in-Time, Kanban oder One-Piece-Flow-Produktion. Langfristige Planung und gezielte Materialreserven sorgen für eine stabile Versorgung und optimierte Ressourcenutzung.

Are you looking for an experienced and reliable system supplier in Switzerland?

Decide to outsource individual or all product creation processes to us. We will be happy to support you on your way to success.

Auftragsabwicklung

Nach der gemeinsamen Auftragsklärung übernehmen wir die Terminkoordination und Vernetzung und Kommunikation mit Ihnen und unseren, bzw. Ihren Lieferanten über digitale Kanäle.

Qualitätssicherung

Durch regelmässige Qualitäts- und IT-Schulungen stellen wir sicher, dass unser eingespieltes Team aus qualifizierten Ingenieuren, Fertigungstechniker und Montage-Experten ein gemeinsames Qualitätsverständnis pflegt und der konsequenten, operativen Umsetzung der ISO:9001 Normanforderungen verpflichtet bleibt.

So sind unsere Mitarbeiter:innen qualifiziert im Umgang mit:

- Top-secure, digital infrastructure and state-of-the-art technical and IT equipment

- Material analyses and quality tests (functional, burn-in and factory acceptance tests)

- Komplett digitalisierte Dokumentation und PDM

- Berichterstellung an Sie und unsere, bzw. Ihre Lieferanten

Einkauf

Wir beschaffen Bauteile über Ihr oder unser eigenes Lieferantennetzwerk. Für eine maximale Ressourcenoptimierung überwachen wir kontinuierlich den Beschaffungsmarkt und planen und optimieren integrierte Beschaffungskonzepte entsprechend.

Dank unserer modernen IT-Infrastruktur und komplett digitalisierten Fertigungsprozessen können wir die lückenlose Rückverfolgung der für Ihre Produkte verwendeten Rohmaterialien garantieren.

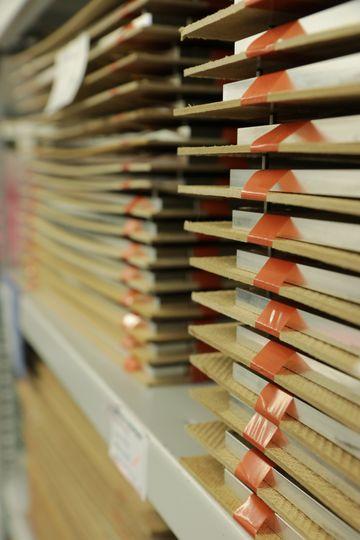

Warenannahme und Lager

- We process and record material deliveries.

- We perform incoming goods inspections and material analyses.

- We evaluate component quality and evaluate defects.

- We store your components.

Lieferanten und Feedback

At CrossTEQ, all our actions are geared towards a future worth living. Thus, we build on valuable relationships with all those who want to shape it with us. Thus, our extensive network consists only of tested, qualified and 90% Swiss suppliers and partners, who measure success, like us, on permanently highest quality, long-term and reliability.

We rely on adequate reserve and redundancy to avoid supply bottlenecks and deliver to you with quality and on time.

Sollte die Materialqualität dennoch ungenügend sein, erstatten wir Bericht an Sie und unsere, bzw. Ihre Lieferanten als Grundlage für den weiteren Einkauf.

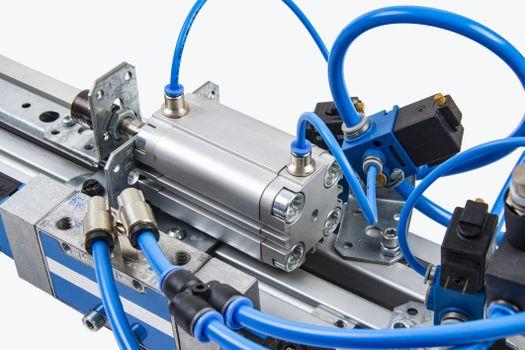

Baugruppenmontage

In our Cross Assembly, we adjust, assemble and test your electromechanical assemblies and devices in product-specific assembly lines.

Wir fertigen im Just-in-time-, Kanban- oder One-Piece-Flow-Verfahren für einen effizienten Produktionsdurchlauf und maximale Ressourcenoptimierung.

Verpackung und Distribution

We pack assemblies and complete units according to your requirements and coordinate shipping. We work with certified logistics companies for the DACH region to deliver your products to you or your customers - on time and in quality.

Service und Reparatur

Defekte Produkte werden von uns zurückgenommen, repariert und umfassend analysiert. So gewinnen wir wertvolle Erkenntnisse für Optimierungen. Zusätzlich übernehmen wir das Ersatzteilmanagement, um reibungslose Abläufe sicherzustellen.

Produkt- und Produktionsoptimierungen

As early as the development phase, we consider potential and further development planning and accompany its ramp-up from the point of view of automation potential and its economic scalability.

Quality und Product Data Management

Wir dokumentieren und überwachen konsequent sämtliche Daten und alle Produktionsprozesse auf unserer sicheren IT-Infrastruktur. Dadurch gewährleisten wir:

- Einen nahtlosen Informationsfluss mit unseren Kunden, Lieferanten und Mitarbeitern in Echtzeit

- Lückenlose Zurückführung von Material, Bauteilen, Abweichungen und Ausfällen

- Die sofortige Erkennung von Fehlern und Risiken

How we work

Bei CrossTEQ richten wir unser Handeln konsequent auf eine lebenswerte Zukunft aus. Unser Ziel ist es, starke Partnerschaften aufzubauen – mit Menschen, die gemeinsam mit uns Zukunft gestalten und dabei Vertrauen, Ideen und Kompetenz in unser Unternehmen einbringen.

Um großartige Swissmade-Produkte und eine erfolgreiche Zusammenarbeit zu fördern, setzen wir auf einen offenen und dynamischen Austausch mit unseren Partnern und Mitarbeitern.

Unser Erfolg misst sich an höchster Qualität und Zuverlässigkeit. Wir sind stolz auf unsere Swiss Excellence und stärken unser gemeinsames Qualitätsbewusstsein jeden Tag aufs Neue.

Communication

Agilität und Kollaboration sind uns wichtig. Wir schätzen den transparenten und dynamischen Austausch mit unseren Kunden, Lieferanten und Mitarbeitern, um auch auf sich ändernde Anforderungen gezielt und effektiv reagieren und die besten Produkte für Sie realisieren zu können.

Vision

Bereits in der Entwicklungsphase machen wir uns Überlegungen zu Reparierbarkeit, Optimierungen und Weiterentwicklungen Ihres Produktes. Wir planen sein Ramp-up vom Blickpunkt des Automatisierungspotenzials und dessen wirtschaftlicher Skalierbarkeit.

Data & Security

Wir dokumentieren und überwachen konsequent sämtliche Daten und alle Produktionsprozesse auf unserer hochsicheren IT-Infrastruktur. Dadurch erkennen wir Fehler und Risiken sofort und können Abweichungen lückenlos zurückführen.

Co-Engineering

Sie profitieren von einer jahrelangen Erfahrung in der Baugruppenentwicklung und Konstruktion für renommierte Unternehmen in der Medizintechnik, dank der engen Partnerschaft mit unserem Schwesterunternehmen Getronic Engineering AG.

Das sind die Chancen und Herausforderungen im Supply Chain Management heute

Wieso Supply Chain Prozesse überhaupt outsourcen?

Reibungslose Wertschöpfungs- und Lieferkettenprozesse sind ein wichtiger Erfolgsfaktor in Unternehmen. Doch sind Supply Chain Aktivitäten zugleich auch umfangreich und mit hohen Kosten verbunden. Gerade zu Zeiten des Fachkräftemangels stellen die komplexen Aufgaben des Supply Chain Managements Unternehmen deshalb vor grosse Herausforderungen.

Das sind die Herausforderungen im Supply Chain Management heute

Komplexität durch Heterogenität

Entlang einer Wertschöpfungskette herrscht grosse Heterogenität unter mehreren Ebenen, vielen Unternehmen und unzähligen Abteilungen, die alle mit unterschiedlichen Kompetenzen teilweise gegensätzliche Ziele verfolgen (günstig einkaufen, teuer verkaufen).

Um zu funktionieren, müssen alle Beteiligten einer Wertschöpfungskette durch Supply Chain Management ihre Ziele in Einklang bringen und miteinander kooperieren.

Vertrauensaufbau und Zuverlässigkeit

Kooperation erfordert ein hohes Maß an Vertrauen und Verlässlichkeit. Kommt ein Glied seinen Verpflichtungen nicht nach, hat das Auswirkungen auf die gesamte Kette.

Nur wenn alle Beteiligten durch integriertes Supply Chain Management ihre gemeinsamen Ziele verfolgen, können Waren-, Geld- und Informationsflüsse sicher und reibungslos stattfinden.

Steigerung der eigenen Flexibilität und Reakitonsfähigkeit

Unvorhergesehene bzw. unvorhersehbare Aufgaben können die routinemässigen, Arbeiten, die Sie regelmäßig erledigen und langfristig planen können, erheblich einschränken. In den meisten Fällen fehlen die Ressourcen, um die alle Probleme in angemessener Zeit zu lösen.

Da Aufgaben und Prozesse auch kurzfristig ausgelagert werden können, gewinnen Sie mit einem Outsourcing Partner schnell Ressourcen und damit ein an hohes Mass an Flexibilität.

Das sind die Chancen im Supply Chain Management heute

Kundenzufriedenheit ist der Schlüssel zu einem nachhaltigen, langfristigen Unternehmen, und dies kann nur erreicht werden, wenn die Wertschöpfungsketten optimal funktionieren. Die Auslagerung solcher Prozesse und Prozessketten an einen spezialisierten Partner können dazu beitragen, das Risiko einer ineffizienten Wertschöpfungskette zu minimieren.

Besser mit personellen Ressourcen, Technologien und den effektiven Prozessen ausgestattet, können Drittanbieter einen reibungslosen und effizienten Ablauf aller Lieferkettenprozesse langfristig gewährleisten und sich besser an veränderte Bedingungen anpassen.

Lesen Sie jetzt weiter, und erfahren sie, wann und wieso es sich lohnen kann, Supply Chain Management Prozesse an Dritte auszulagern.

Gründe für die Auslagerung von Supply Chain Prozessen

Kosteneinsparung

Es ist oft kostengünstiger, die Lieferkette an einen zuverlässigen Dritten auszulagern, als sie selbst zu verwalten. Angefangen bei geringeren Lagerkosten können Sie durch die Auslagerung von Wertschöpfungs- und Lieferprozessen vor allem bei Personalkosten (inkl. Lohnnebenkosten) und Kosten für Räumlichkeiten und das benötigte Equipment sparen.

Risikominimierung

Wird die Lieferkette an ein einen Partner in Übersee ausgelagert, mögen die Einsparungen zwar kurzfristig höher sein. Doch sind kürzere Lieferketten um einiges flexibler und langfristig stabiler, da sie schneller auf Trends reagieren und damit längerfristig Kosten einsparen.

Steigerung der eigenen Flexibilität und Reakitonsfähigkeit

Unvorhergesehene bzw. unvorhersehbare Aufgaben können die routinemässigen, Arbeiten, die Sie regelmäßig erledigen und langfristig planen können, erheblich einschränken. In den meisten Fällen fehlen die Ressourcen, um die alle Probleme in angemessener Zeit zu lösen.

Da Aufgaben und Prozesse auch kurzfristig ausgelagert werden können, gewinnen Sie mit einem Outsourcing Partner schnell Ressourcen und damit ein an hohes Mass an Flexibilität.

Wertsteigerung der eigenen Produkte / Dienstleistungen

Externe Partner verfügen über Kompetenzen, Lösungen und Fachwissen, für deren Aufbau Ihr Unternehmen unter Umständen mehrere Jahre und grosse Investitionen benötigen würde.

Sie profitieren jedoch nicht nur vom eingebrachten Planungs- und Fachwissen; Für seine operative Exzellenz nutzt ein spezialisierter Dienstleister über Ausrüstung und Werkzeuge, die dazu beitragen, die Effizienz und Produktivität Ihrer Supply Chain Prozesse zu steigern.

Durch die Beauftragung von Spezialisten sparen Sie also eigene Ressourcen bei Personal, Infrastruktur und Technologie und können diese stattdessen effizienter an internen Schlüsselstellen wie Forschung, Entwicklung und Optimierung der eigenen Produkte und Dienstleistungen einsetzen.

Fokus auf eigene Kernkompetenz

Tätigkeiten außerhalb der Kernkompetenzen sind oft ineffizient und können nicht zuletzt zu Zeitverzögerungen und fatalen Einbussen im Kerngeschäft führen. Durch das Outsourcen einzelner Aufgaben oder sämtlicher Aufgabengruppen entlang der Supply Chain an externe Dienstleister, gewinnen Sie mehr Zeit, um Ihren Fokus auf die Entwicklung Ihres Kerngeschäfts zu richten.

Fazit

Kundenzufriedenheit ist der Schlüssel zu einem nachhaltigen, langfristigen Unternehmen, und dies kann nur erreicht werden, wenn die Wertschöpfungsketten optimal funktionieren. Die Auslagerung solcher Prozesse und Prozessketten an einen spezialisierten Partner trägt dazu bei, das Risiko einer ineffizienten Wertschöpfungskette zu minimieren, was die Kundenbeziehungen und Rentabilität ernsthaft beeinträchtigen kann.

Besser mit personellen Ressourcen, Technologien und den effektiven Prozessen ausgestattet, können Drittanbieter einen reibungslosen und effizienten Ablauf aller Lieferkettenprozesse langfristitig gewährleisten und sich besser an veränderte Bedingungen anpassen.

Die Ressourcen und das Fachwissen der Outsourcing Partner sind besonders dann wertvoll, wenn Sie Ihre Produktion entsprechend der schwankenden Nachfrage im Absatzmarkt skalieren müssen.

Your advantages with CrossTEQ as a partner

Streamlining processes

Durch die Auslagerung Ihrer Baugruppenmontage und anderen Aufgaben und Produktionsprozessen an uns, verschlanken Sie Ihr eigenes Unternehmen und bleiben agil.

Save resources

By entrusting us with the assembly of your subassemblies, you save your own resources in terms of personnel, infrastructure and technology and can instead deploy them more efficiently at key internal points.

Pragmatic and efficient

Bei CrossTEQ pflegen wir eine dynamische Personal- und Produktionsplanung, effiziente Fertigungsprozesse und kurze Kommunikationswege sowohl mit unseren Kunden als auch mit unseren, bzw. Ihren Lieferanten.

Maximum reactive and flexible

Wir bauen auf sichere Quellen und verhältnismässige Reserven und Redundanz bei der Material- und Personalplanung, um auch bei kurzfristigen Montage-Aufträgen termin- und qualitätsgerecht an Sie liefern zu können.