Composite Engineering & Composite Material Design

Wir ermöglichen die gezielte Nutzung der hervorragenden Materialeigenschaften von thermoplastischen Faserverbundwerkstoffen. Gerne helfen wir Ihnen, an alles zu denken wenn Sie sich für Faserverbundwerkstoffe entscheiden.

Full Composite Material Lifecycle

From raw materials (fibers and polymers), design and suitable manufacturing processes, to final component testing and qualification:

We have broad expertise in fiber-reinforced composites and can competently guide your composite project through all phases.

Fiber architecture & load paths

We specialize in the design and layout of fiber composite components with continuous and discontinuous fiber architecture.

Especially in the field of discontinuous fiber reinforcement, the company uses models developed in research collaboration (FHNW) to predict material properties.

Mechanical analysis

Dank modernster FEM-Tools sind wir in der Lage, die mechanischen Eigenschaften von komplexen Mehrkörperstrukturen zu analysieren. Engineering-Tools, die auf der klassischen Laminat-Theorie (CLT) basieren, und speziell entwickelte Tools für diskontinuierliche Faserverbundwerkstoffe (DFC) ermöglichen es uns, Material- und Bauteileigenschaften präzise vorherzusagen.

Konstruktion von Materialeigenschaften

- Lightweight

- Strength & Stiffness

-

Pressure & Temperature Resistance

- Corrosion & Chemical Resistance

- Radioluscent

- UV-stability

- Bio- & skin compatibility

- Toughness & damping behavior

- Tribology

Thanks to intelligent material design and application-specific production technologies (X-Technologies), we can design the outstanding properties of thermoplastic fiber composites specifically for different component geometries and functional free-form surfaces.

In unserem Composite Kompetenzzentrum entwickeln wir dafür anwendungsspezifische Produktionstechnologien und die entsprechenden Sonderanlagen und Formwerkzeuge.

Functionalities & 3D Structures

- Load paths

- Wall thickness jumps

- Bearing seats

- Reinforcement ribs

- Threads

- Inserts

- Undercuts

- Holes

- Openings

CAD Design

We develop and design with the latest version of SolidWorks Professional. SolidWorks is widely used in various industries and guarantees excellent performance in the design of simple to complex 3D geometries.

Strukturen und Funktionalitäten

Intelligentes Material Design für optimale Materialeigenschaften

Unsere Experten verfügen über umfangreiches Material-Knowhow und helfen Ihnen, an alles zu denken wenn Sie sich für Faserverbundwerkstoffe entscheiden.

Wir helfen Ihnen bei der Materialauswahl und konfigurieren für Sie thermoplastisches Composite-Verbundmaterial gemäss Ihren spezifischen Produktanforderungen.

This allows us to create unique surface finishes, textures and functional open surfaces for your product.

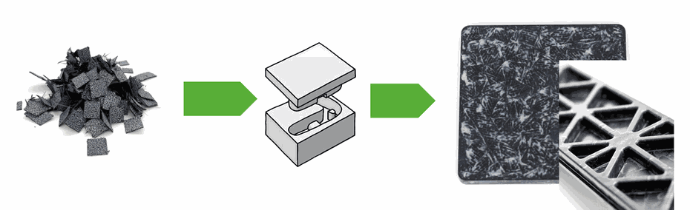

Eco Design

For years, we have worked on the recyclability of our products to achieve a successful cradle-to-cradle cycle without downcycling. CrossTEQ composite components are fully recyclable and therefore contribute significantly to the conservation of natural resources.

Thanks to our practical knowledge of the eco-design of composite parts, we can support you with questions such as:

-

How do you avoid using metal inserts or rivets?

-

Which fiber architecture is easiest to recycle?

- Welche Arten von Polymeren sind die beste Wahl für Ihr Teil?

The elimination of metal inserts in all CrossComposite products not only results in more environmentally friendly monomaterials, but also in significantly lighter components.

Form, functionality, properties or esthetics: What are your challenges?

Machen Sie einige unverbindliche Angaben über das Formular oder besuchen Sie unser Kompetenzzentrum. Gerne beraten wir Sie in allen Phasen Ihres Verbund-Projektes.